Heating and Cooling

Penstar has been approached to find solutions to clients' problems concerning heating and cooling processes:

Water circulation and heating

The problem:

The client is a printing company specialising in producing plastic packaging for many well-known high street names.

In the process, the printing roller is heated using circulating hot water which must be controlled within very close temperature limits. Several colours are printed simultaneously and any variation in temperature causes slight changes in the relative positioning of the colours. The unreliability or the original unit was causing difficulties in production.

Penstar provide system to keep circulating process water at a constant process temperature:

Our unit enclosed within a steel housing, included a water pump and in-line water heater. The temperature of the water from the heater is controlled using a three term electronic controller and power to the heater regulated using a silicon controlled rectifier. A local alarm was provided to indicate if the temperature moves outside high or low limits.

The compact package was manufactured and tested in our workshops with flexible connections for minimum on-site installation. We delivered and installed the unit and our commissioning engineers set up the system to meet their requirements.

Quench water cooling

The problem:

The client is a metals foundry where drums of cable a quenched in a large sump of water. The water needed to be cooled each time it was used in readiness for the next batch. The client had a water chiller available but this was not suitable to be used directly because of the temperature of operation and the likelihood of being fouled by the dirty water.

Penstar provide system to utilise the existing equipment to cool the quench water:

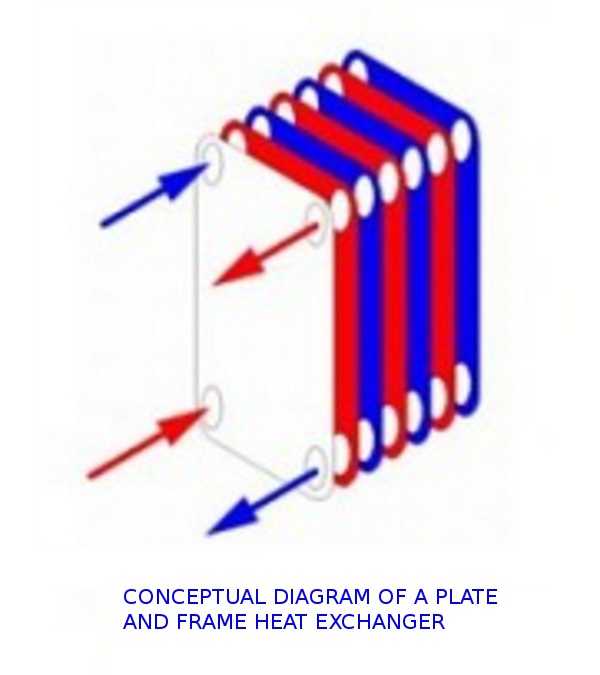

The warm water was circulated through a heat exchanger, which was cooled using a secondary circulation system through the chiller. The control system used a variable temperature control unit, with a sensor located in the sump and there was a manual option to transfer water from the sump to the works main cooling system for water treatment.